PRODUCTS

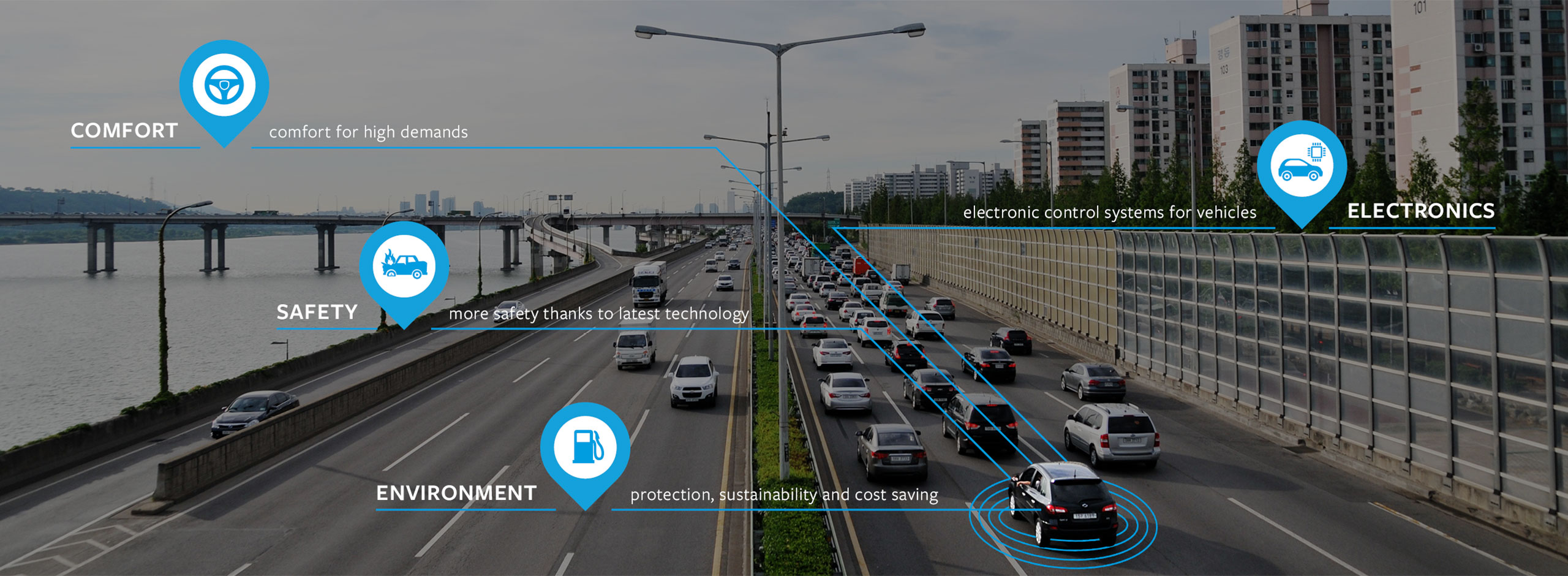

As a “Tier 2” supplier, we support the largest automotive companies worldwide. The automotive industry is our core business but we also work with water treatment and electrical engineering customers. To discover all of the group’s mechatronic expertise, click here.

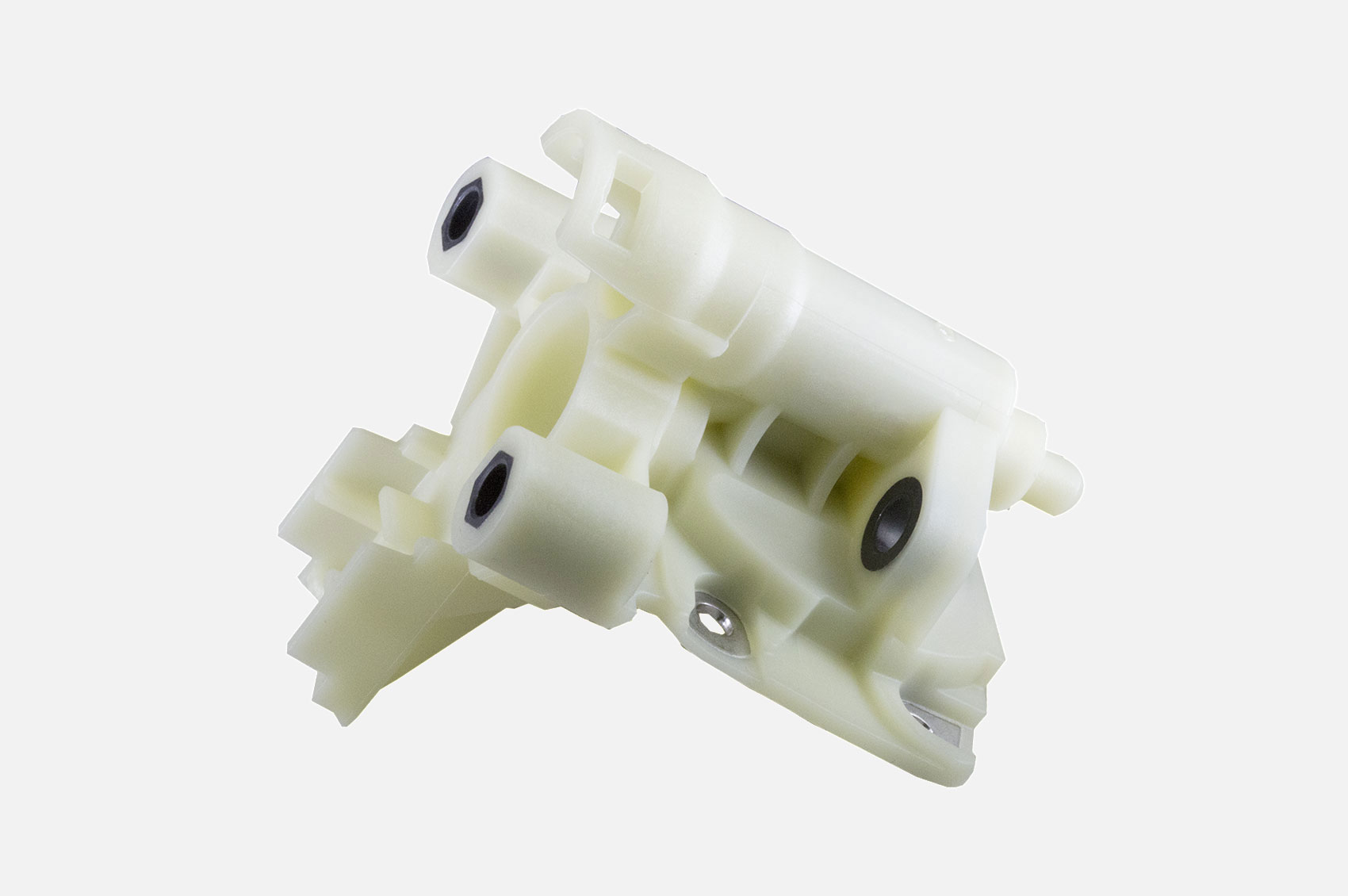

HOUSING

Use | Application:

Air suspension

Material:

PPA + 50% fiberglass

Process:

1 shot injection molding, residual humidity measurement, burst pressure test

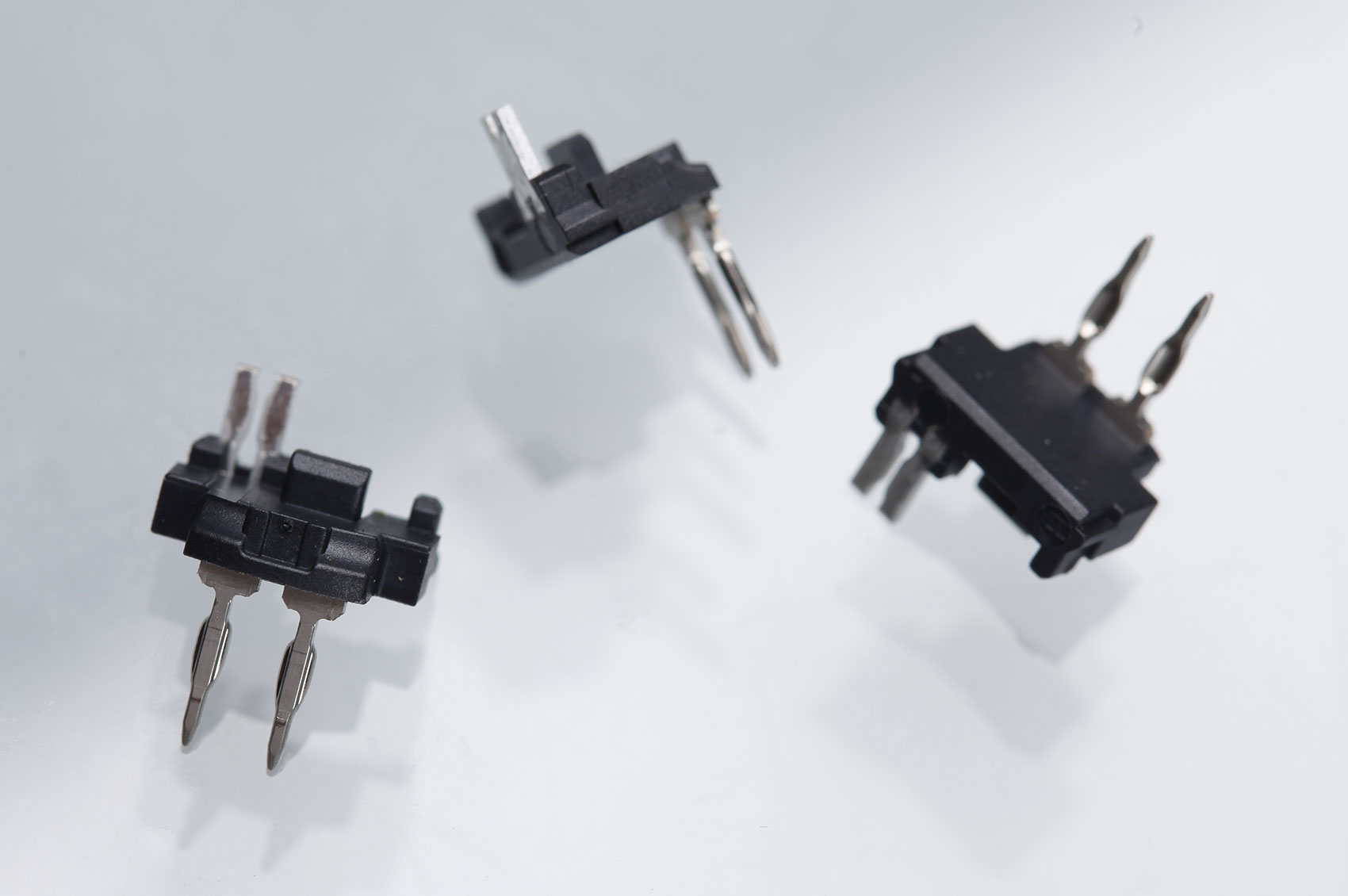

CONNECTOR, PARK ASSISTANT

Use | Application:

Ultrasonic sensor

Material:

PBT + 30% fiberglass

Process:

Press-fit technology, insert overmolding

CONTACT CARRIER, PARK ASSIST SENSOR

Use | Application:

Ultrasonic sensor

Material:

PBT + 30% fiberglass

Process:

Reel-to-reel, overmolding of press-fit pins

PRESSURE SENSOR

Use | Application:

Airbag system

Material:

PBT + 30% fiberglass

Process:

Press-fit technology

LOW PRESSURE SENSOR

Use | Application:

Brake booster

Material:

PBT + 30% fiberglass

Process:

Cold contact technology, insert overmolding

MAGNET HOLDER

Use | Application:

Braking system

Material:

POM + 10% fiberglass

Process:

Magnet overmolding

PLUG CONNECTOR

Use | Application:

Urea injection (AdBlue)

Material:

PA6T + 40% fiberglass

Process:

Metal sleeve overmolding

HOUSING

Use | Application:

Urea injection (AdBlue)

Material:

PPA + 33% fiberglass

Process:

Overmolding

PLUG

Use | Application:

Start-stop sensor

Material:

PA6-12 + 33% fiberglass

Process:

Pins Overmolding

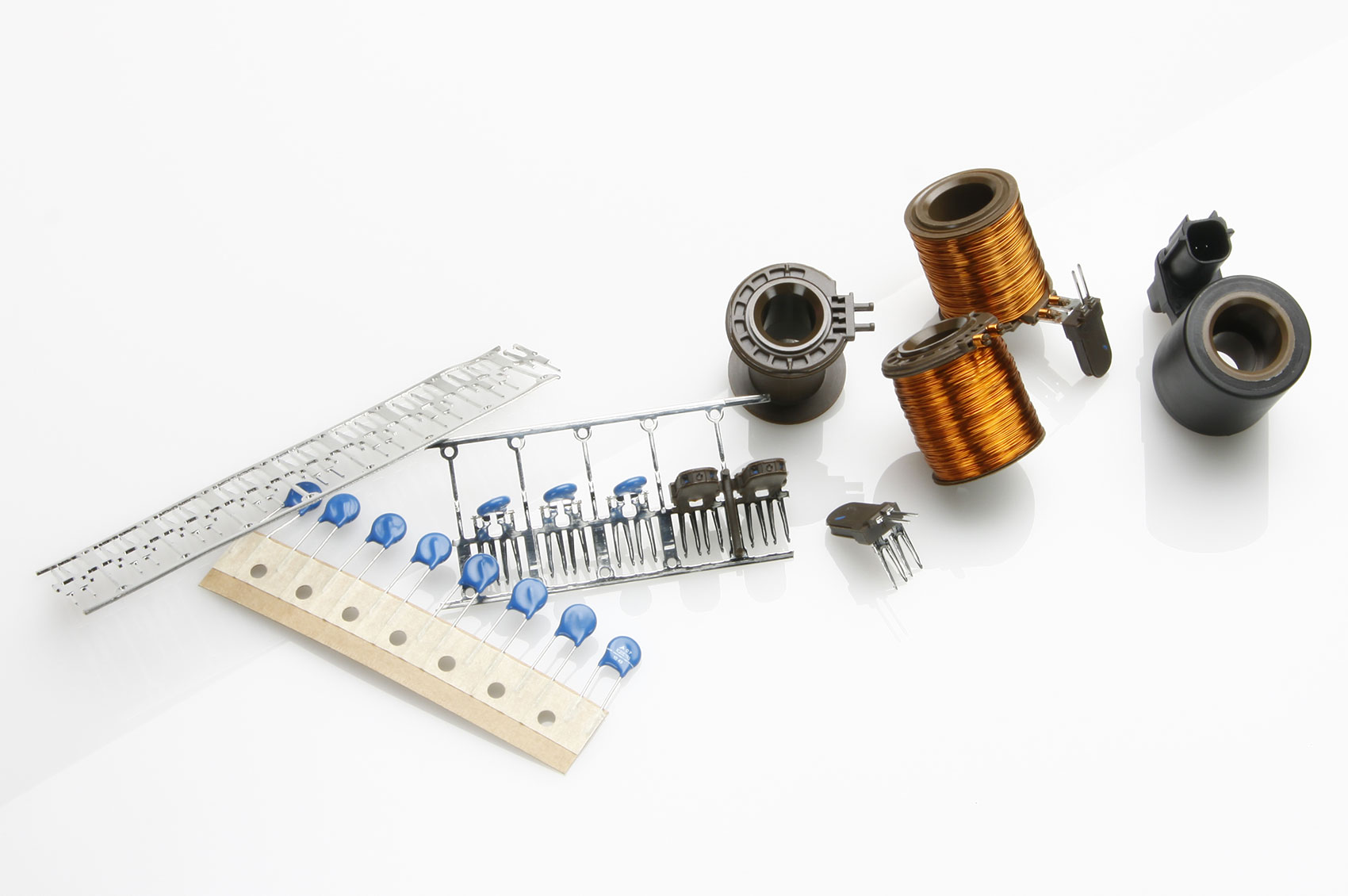

SOLENOID

Use | Application:

Cooling system valve

Material:

PPS + 40% fiberglass

Process:

Reel-to-Reel, winding, e‑welding, insert overmolding

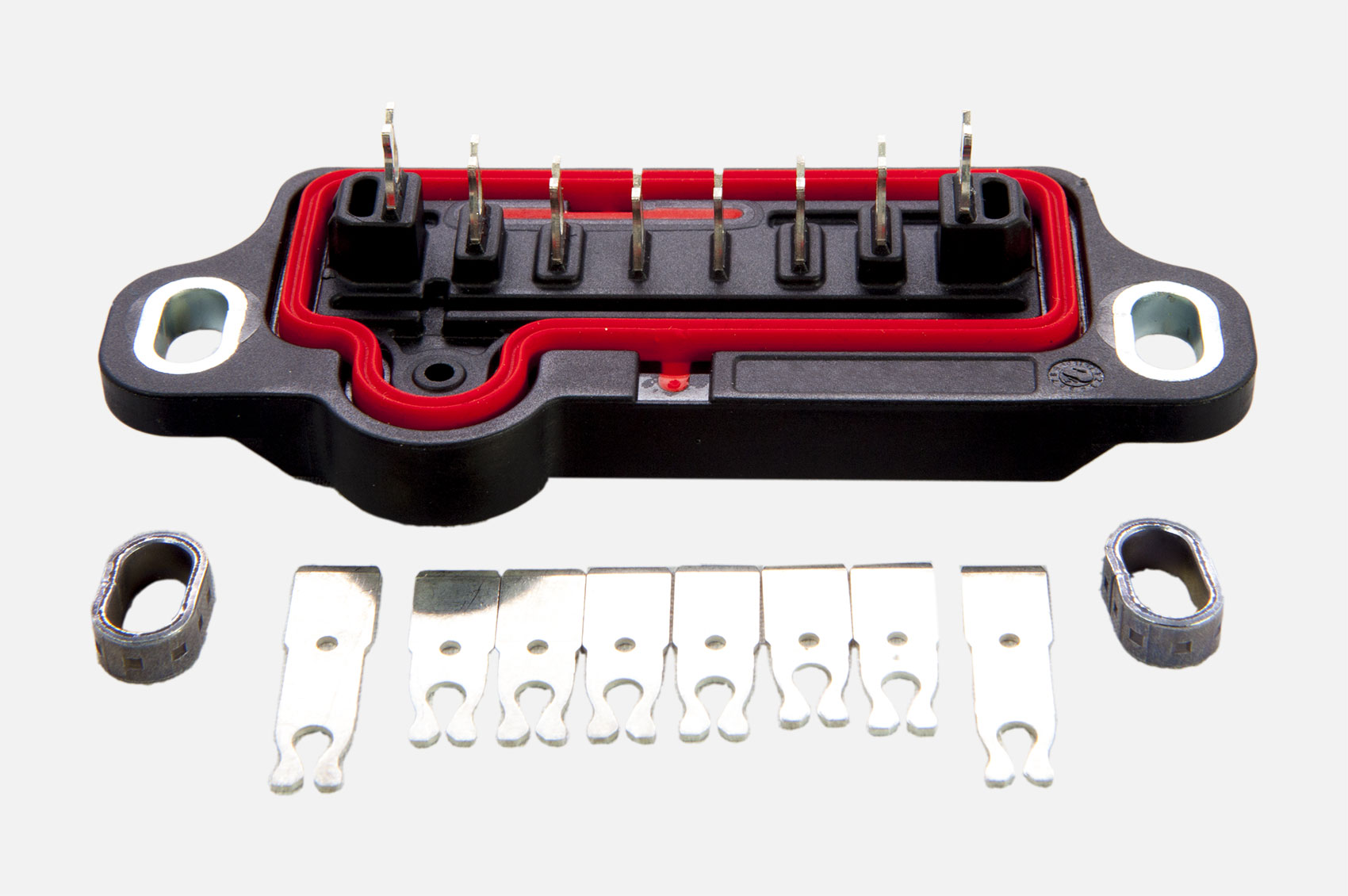

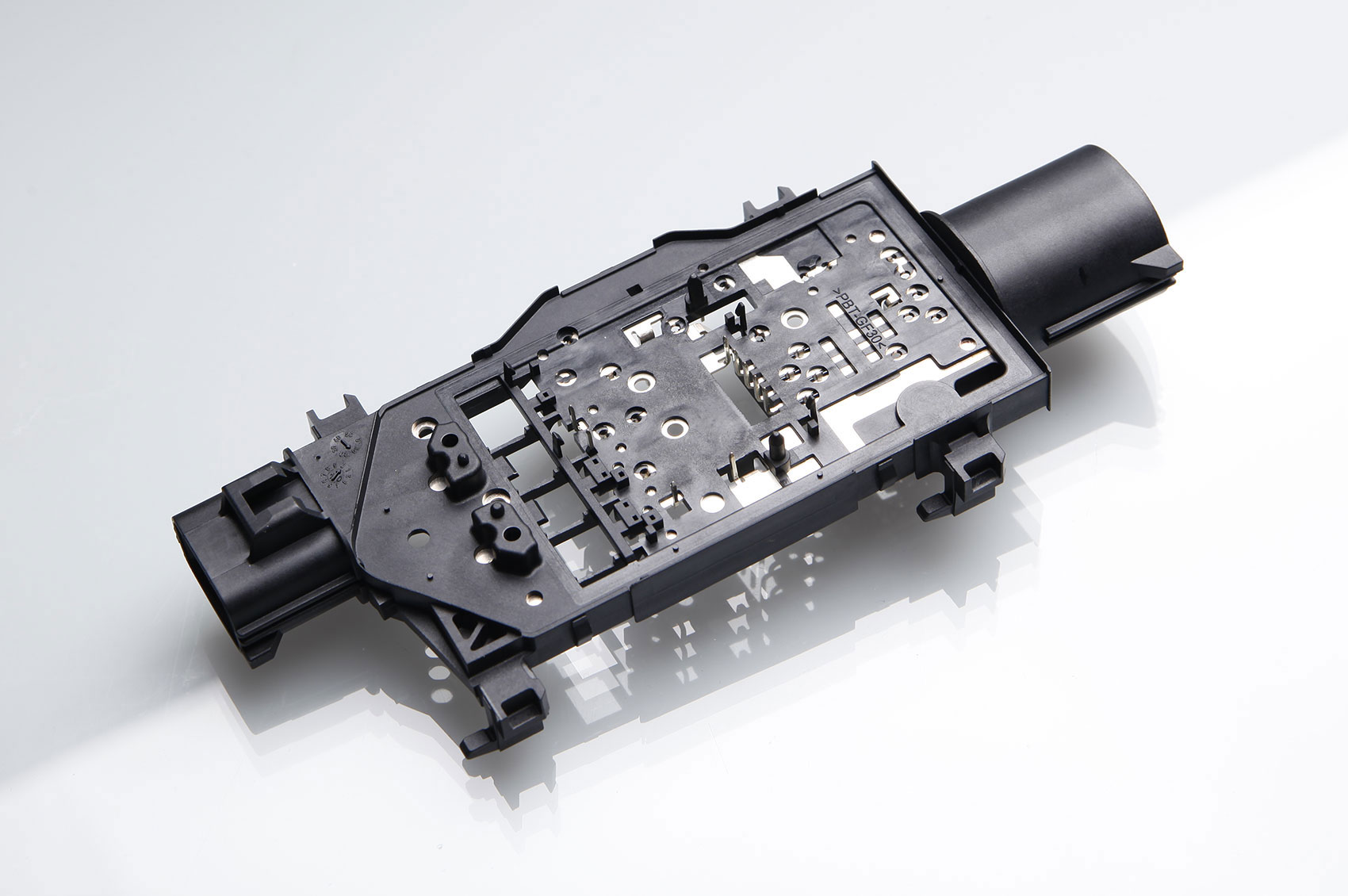

CONTACT PLATE

Use | Application:

Steering assistance

Material:

PBT + 30% fiberglass + LSR

Process:

Overmolding, gasket, potting, DAE-membrane

CONTACT CARRIER

Use | Application:

Steering assistance

Material:

PPA + 30% fiberglass

Process:

Insert overmolding, automated assembly, tape & reel packaging

ESD COVER

Use | Application:

Throttle valve controller

Material:

PBT + 30% fiberglass

Process:

Reel-to-Reel, ESD clean room production

HOUSING

Use | Application:

Air suspension

Material:

PPA + 50% fiberglass

Process:

1 shot injection molding, residual humidity measurement, burst pressure test

CONNECTOR, PARK ASSISTANT

Use | Application:

Ultrasonic sensor

Material:

PBT + 30% fiberglass

Process:

Press-fit technology, insert overmolding

CONTACT CARRIER, PARK ASSIST SENSOR

Use | Application:

Ultrasonic sensor

Material:

PBT + 30% fiberglass

Process:

Reel-to-reel, overmolding of press-fit pins

PLUG

Use | Application:

Window lifter

Material:

PA66 + 25% fiberglass + TPE

Process:

2 shot injection molding, insert overmolding

PRESSURE SENSOR

Use | Application:

Airbag system

Material:

PBT + 30% fiberglass

Process:

Press-fit technology, insert overmolding

LOW PRESSURE SENSOR

Use | Application:

Brake booster

Material:

PBT + 30% fiberglass

Process:

Cold contact technology, insert overmolding

MAGNET HOLDER

Use | Application:

Braking system

Material:

POM + 10% fiberglass

Process:

Magnet overmolding

PRESSURE SENSOR

Use | Application:

Active pedestrian protection

Material:

PBT + 30% fiberglass

Process:

Cold contact technology | insert overmolding

PLUG CONNECTOR

Use | Application:

Urea injection (AdBlue)

Material:

PA6T + 40% fiberglass

Process:

Metal sleeve overmolding

HOUSING

Use | Application:

Urea injection (AdBlue)

Material:

PPA + 33% fiberglass

Process:

Overmolding

PLUG

Use | Application:

Start-stop sensor

Material:

PA6-12 + 33% fiberglass

Process:

Pins Overmolding

PLUG

Use | Application:

Diesel injection

Material:

PA6 + 35% fiberglass

Process:

Insert overmolding

SOLENOID

Use | Application:

Cooling system valve

Material:

PPS + 40% fiberglass

Process:

Reel-to-Reel, winding, e‑welding, insert overmolding

CONTACT PLATE

Use | Application:

Steering assistance

Material:

PBT + 30% fiberglass + LSR

Process:

Overmolding, gasket, potting, DAE-membrane

CONTACT CARRIER

Use | Application:

Steering assistance

Material:

PPA + 30% fiberglass

Process:

Insert overmolding, automated assembly, tape & reel packaging

ESD COVER

Use | Application:

Throttle valve controller

Material:

PBT + 30% fiberglass

Process:

Reel-to-Reel, ESD clean room production